Summary

Introduction

Midi-Formatique SARL, a limited liability company, was created in 1999

in the "Plein Sud Entreprises" technology center at Rivesaltes, France.

Its field of operation is software programming and training; it is

specialized in image analysis and industrial automation.

Midi-Formatique SARL, a limited liability company, was created in 1999

in the "Plein Sud Entreprises" technology center at Rivesaltes, France.

Its field of operation is software programming and training; it is

specialized in image analysis and industrial automation.

Founder and manager is Tilman JOCHEMS, born in 1962 at Lübeck,

Germany. He is an engineer with a Diploma in Electrical Engineering

from the Technical University of Aachen, Germany, and a PhD in

Mathematical Morphology from the School of Mines of Paris, France.

Since 2015, our head office is in Saint-Cyprien.

We offer

you a complete service, from the analysis of a problem to its practical

solution.

We offer

you a complete service, from the analysis of a problem to its practical

solution.

We carry out ourselves the automation and data processing

involved. As far as the mechanical and electrical side is concerned, we

collaborate with local companies.

We also maintain and optimize existing installations.

As experts in image analysis, we offer training in

mathematical morphology and signal processing.

Top

Top

Realizations

In this chapter, we present our latest projects. For

additional information, please contact

us.

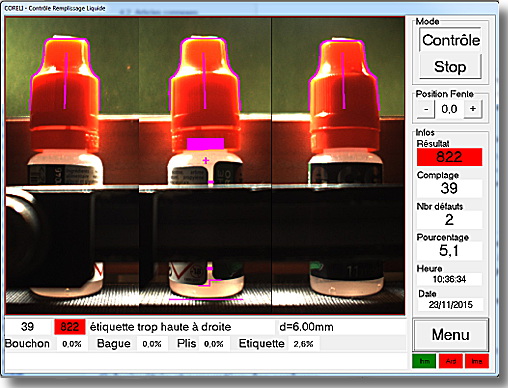

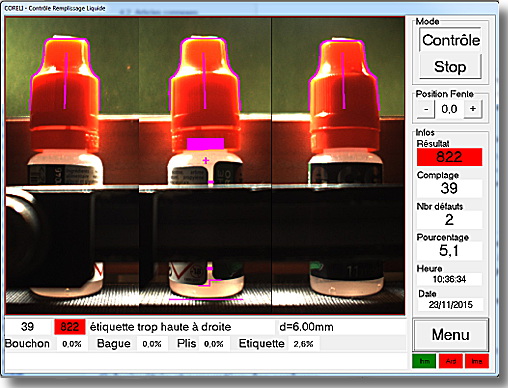

Control of e-liquid

filler by image analysis

The problem: at the end

of a filling line, control of the

bottles including caps, rings and labels was needed. Our customer's

request: 100% defect detection before the automatic packaging.

Our realisation: image

acquisition with an Allied

Visions GigE camera / image analysis using Qlisp5.0

under Windows 8 /

synchronisation of the camera and ejection of bottles with an Arduino

Ethernet card.

We realised specific pages in order to configure the

algorithm, to

display and export statistics of the production and to give a history

of the defects.

Controls: position and

inclination of caps, position

of rings, existence and position of the labels, detection of wrinkles.

These results are marked in purple on the right side image.

Performance: 2 products/s

The installation works since may 2015 and replaced an existing

vision

control. Our client is satisfied, the algorithm works without the

operator's intervention with all caps and labels used.

Début

Début

Driving a

machine with the help of image analysis

The problem: a complex machine was

difficult to drive. A manual adjustment was needed all

the time in order to position the product for a consecutive

machining.

Our idea: help the driver with a program

based

on image analysis.

Used equipment: colour camera, GigE

Vision, PoE,

Allied Vision Technologies / industrial computer, fanless, Panel Pc,

Advantech / switch, PoE, Netgear.

Realization: image acquisition via

Ethernet, data processing by using a software

based on Qlisp 5.0, graphical user interface with touch

screen, communication of the results to an OMRON PLC with FINS (factory

intelligent network service).

Our client is satisfied: the installation positions the

product with an accuracy of 0.1mm and a frequency of 0.5s.

Top

Top

Individual braking

Description:

the bobbins of a machine for textile manufacturing must be braked

individually. The torque has to be modified dynamically according to

the diameter of each bobbin to obtain a constant tension of the threads.

Description:

the bobbins of a machine for textile manufacturing must be braked

individually. The torque has to be modified dynamically according to

the diameter of each bobbin to obtain a constant tension of the threads.

Our idea: measuring the diameters of each

bobbin by a process of impulse counting.

Realization: electrical equipment (see the

photograph) with an OMRON controller and an industrial computer

allowing to control up to 96 brakes (MEROBEL). Inductive sensors

transmit the state of each bobbin through an industrial network to the

controller. This device calculates the diameters of the bobbins and

deduces analogue braking values. The values are transmitted to

amplifiers that actuate the brakes. A computer equipped with a touch

screen serves as user interface. The computer contains a database that

allows processing different products. The individual characteristics of

each brake are stored in this database to obtain the exact adjustment

of braking.

This installation was realized in collaboration with OCéA,

Canohès.

Top

Top

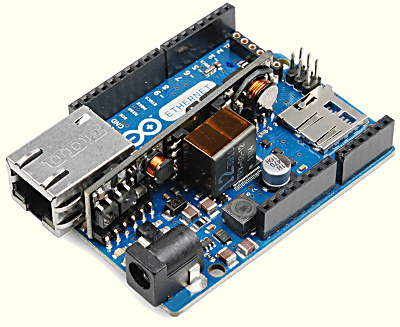

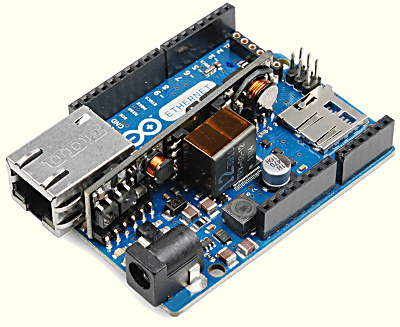

Remote measurements

Request: a customer asked us to record

measurements on several machines. Our

installation should work in a heterogeneous automation environment

without modifying the existing installations.

Our proposition: independent modules based

on Arduino

Ethernet PoE cards (PoE=power over Ethernet).

These cards are programmable in C and allow the capture of about ten

digital signals (including 2 suitable for quick counting) and six

analogue signals. Data transfer and power is provided by simple

Ethernet cables which may have a length up to 100m. A central switch

and an industrial computer ensure the recording of the data in a

database. Our proposed software allows printing of reports or exporting

in csv format.

Realization: equipment of several machines

with measurement modules, realization of

distance sensors based on the Sharp GP2Y, program in C++ for a Panel PC

with touch screen and bar-code scanner.

The installation works correctly 24/7 since several months.

Top

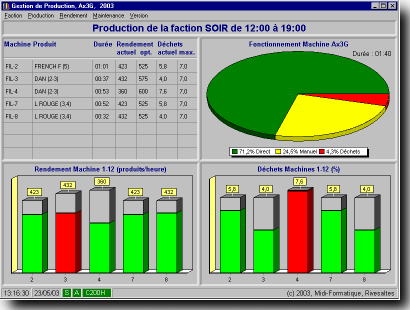

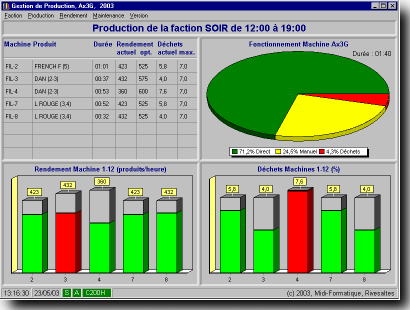

Production recording

Description: several machines had been

joined together to form a manufacturing unit. This allowed more

efficient production, but made the detection of machine anomalies more

difficult.

Realization: a program for keeping track of

production. Each arriving and outgoing product is recorded. The graphic

interface shows how the installation is working at a given moment. A

database stores the results of manufacture. Consulting it allows the

maintenance service to check the output of each machine and the

percentage of its waste.

Top

Top

Positioning a

colour camera

Description: a colour camera was installed

to enhance the quality of paper production. The operators can now

control on a screen the structure of the fast moving paper. An electric

motor produced by EMERSON moves the camera into the desired position.

Realization: a software interface (DLL)

allowing the positioning of the camera via the Modbus protocol,

programming of the motor's controller.

The installation was realized in collaboration with OCéA,

Canohès and VISISCAN, Paris.

Top

Top

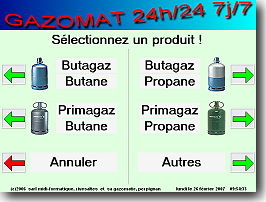

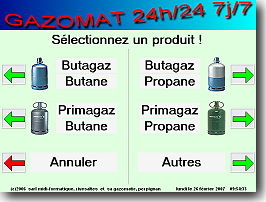

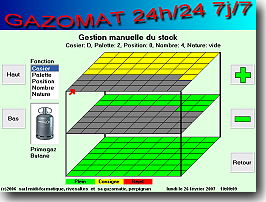

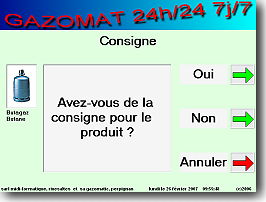

Distribution

automat

Advantages: purchase by credit card;

independence of gasoline stations and supermarkets; 24h/24

availability; customers comfort who can leave their cars directly in

front of the automat; and especially: filling of the distribution

automat by crane or lifting truck which will reduce the costs of

delivery.

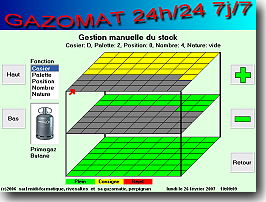

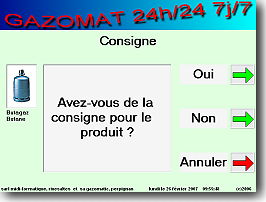

Realization: we have realized a functional

prototype, the company Midi-Formatique conceived and carried out all

the data-processing/automatism part. The power equipment (robot of 3

axes, doors of lock,...) is ordered by the controller CJ1M of OMRON

which permanently exchanges its information with an industrial computer

(protocol toolbus). The computer presents also the graphical interface,

manages the stock (database), informs the deliveryman by email about

out-of-stock condition, allows remote maintenance, communicates with

the payment unity, prints tickets, ...

Unfortunately, this project was abandoned for personal reasons.

|

|

|

| Choice of product |

Stock control by service |

Return of consigns |

Top

Top

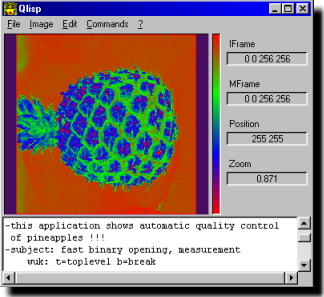

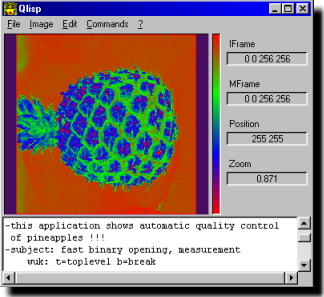

Image analysis system QLISP

We have

developed an image analysis system in order to realize applications in

artificial vision. We also use it for teaching.

We have

developed an image analysis system in order to realize applications in

artificial vision. We also use it for teaching.

The software is based on the Lisp interpreter. We added about

a hundred functions that realize image processing. They are exclusively

programmed in C (mathematical morphology: Dilations, erosions, filters,

segmentation... signal processing: Convolution, Fourier...).

Frame grabbing is possible through standard interfaces

(DirectShow or VideoCapture for MS-Windows, V4L for Linux). You can

treat binary, gray-level or color images.

Qlisp uses the libraries and the sources of Lisp and TclTk,

which are shareware applications. That is why we decided to provide

Qlisp for free in its complete

version, too. Our business remains the design and the

realization of industrial and scientific applications in image analysis.

If you are interested in additional information about Qlisp,

see the chapter about image

analysis.

Top

Top

Rotation control

Description:

a machine requires the rotation control of hundreds of bobbins.

Description:

a machine requires the rotation control of hundreds of bobbins.

Realization: the industrial network AS-i of

the controller RPX from CROUZET allows easy wiring of inductive

sensors, which give information about the rotation of each bobbin. The

machine is stopped in the case of tear; the number of the roller

concerned is communicated via Modbus to the principal controller of the

installation. We carried out the programming of the controller; our

customer provided the mechanical and electrical installation.

Top

Top

Training

Our second activity is teaching. This chapter shows, as an

example, our course "Image Analysis". Practical work is done with our

Qlisp software that we put at your disposal.

Introduction to artificial vision

Contents: cameras (optic, CCD sensor, CCIR standard, digital

interfaces), image analysis systems, basic transformations

(look-up-table, histogram, equalization by histogram), format of

recording, introduction to the software Qlisp (principles, basic

functions, programming).

Duration: 4 hours of lectures, 8 hours of practical exercises

Mathematical morphology

Contents: dilation, erosion, Euclidean and geodetic

distance, counting, ultimate erosion, opening, closing, filters,

algebraic properties of transformations, design of filters,

segmentation, queue-based algorithms.

Duration: 8 hours of lectures, 16 hours of practical

exercises

Signal processing applied to images

Contents: contour extraction and their description by

curvature, convolution of signals, filter construction and

interpretation, Fourier transformation and FFT, filtering in the

frequency space.

Duration: 8 hours of lectures, 12 hours of practical

exercises

If you are interested in training on your premises - in image

analysis or in topics such as programming, TCP/IP, graphical

interfaces, compilation, signal processing - contact us.

Top

Top

Tools

In this chapter we will indicate the tools that we frequently

use for our realizations.

We are convinced that the most important part in a project is

analysis and specification. In this phase, general and theoretical

knowledge of the application and of data processing is required.

As far as the tools are concerned, we remain very open to our

customers' wishes.

|

Field

|

Tools

|

|

Operating systems

|

Windows, Linux

|

|

Data-processing languages

|

C, C++, Lisp, Java, Assembler

|

|

Controllers

|

Omron, Emerson, Beckhoff, Kuka, Crouzet

|

|

Languages of automation

|

Ladder diagram, Grafcet, ... (CEI 61131-3), Basic, Krl

|

|

Internet

|

Html, JavaScript, Php

|

|

Graphical interfaces

|

C++Builder, Tcl/Tk, Api Win32, Owl

|

|

Databases

|

Paradox, dBase, Ldap

|

| Network |

Tcp/Ip, Sockets, Rpc, Com, Smtp |

Home

Home

Top

Vision

Top

Vision

Midi-Formatique SARL, a limited liability company, was created in 1999

in the "Plein Sud Entreprises" technology center at Rivesaltes, France.

Its field of operation is software programming and training; it is

specialized in image analysis and industrial automation.

Midi-Formatique SARL, a limited liability company, was created in 1999

in the "Plein Sud Entreprises" technology center at Rivesaltes, France.

Its field of operation is software programming and training; it is

specialized in image analysis and industrial automation. We offer

you a complete service, from the analysis of a problem to its practical

solution.

We offer

you a complete service, from the analysis of a problem to its practical

solution.

Description:

the bobbins of a machine for textile manufacturing must be braked

individually. The torque has to be modified dynamically according to

the diameter of each bobbin to obtain a constant tension of the threads.

Description:

the bobbins of a machine for textile manufacturing must be braked

individually. The torque has to be modified dynamically according to

the diameter of each bobbin to obtain a constant tension of the threads.

We have

developed an image analysis system in order to realize applications in

artificial vision. We also use it for teaching.

We have

developed an image analysis system in order to realize applications in

artificial vision. We also use it for teaching. Description:

a machine requires the rotation control of hundreds of bobbins.

Description:

a machine requires the rotation control of hundreds of bobbins.